Project photo/K178CH(Image source/KEDING)

Sectional drawing of solid wood flooring(Image source/KEDING)

Laminate flooring

Wood floorings come with a warm texture, distinctive natural hardwood corrugations, and does not have the chilly sensation of tiles. Therefore, it is ideal for a wide range of interior designs and is widely used. Wood floorings come in a variety of styles. The surface materials, plywood, and manufacturing methods have a huge impact on structural integrity, moisture resistance, and longevity. Three types of the most prevalent wood flooring options on the market are solid wood flooring, engineered flooring, and laminate flooring, which will be discussed in this article.

Comparison of wood flooring types (Table source / KEDING)

Comparison of common wood flooring types

| Solid wood flooring | Laminate flooring | 👍Engineered flooring | |

| Surface material | Complete solid wood | Plastic printing | Natural wood veneer |

| Coating treatment | Painting/Pushing oil /UV coating | Aluminum trioxide | UV coating |

| Wood Grain | Cutting from Logs | Printed by computer | Slicing after heat softening |

| 👍KD uses this method of sawing into wood blocks | |||

| Substrate | Complete solid wood | MDF | Plywood |

| Quality | Good touch, natural and beautiful grain, but must be pre-grooved | Plastic material, poor texture | Good touch, natural and beautiful grain |

| Price | High | Low to medium | Medium to medium-high |

| Healthiness | Free formaldehyde | Many manufacturers in the market must be careful to choose the brand | Varies by brand 👍KD Floorings are certified SG Green Label products |

| Moisture resistance | It depends on wood species | Quality varies | 👍Excellent, designed for humid climates |

| Durability | Long service life, but easy to scratch | Short service life, easy to deform the surface joints, high wear resistance, but not scratch resistance | Varies by brand 👍KD uses German environmentally friendly paintfor high hardness, abrasion resistance, and toughness |

| Ease of cleaning | Easy to leave stains, not easy to clean | Easy to clean | Easy to clean |

| Environmental friendliness | Low | Medium | 👍High |

| Installation method | Lay flat, stand high | Floating type | Flat, straight, floating, and elevated |

The comparison of 3 types of wood flooring that you should know

Solid wood flooring

The earliest type of wood flooring is solid wood flooring. Before installation, the entire piece of solid wood is sawn, tenoned, polished, and varnished. Although solid wood floorings was once widely used, it has the drawbacks of being susceptible to moisture, prone to bulge, deform and crack. This limits the options of wood types that may be used as solid wood floorings. At the same time, expansion joints must be reserved to tolerate thermal expansion. However, dust and debris might accumulate more easily in the gaps, which lead to problems such as cleaning difficulties. Furthermore, solid wood floors not only cost more, but also squander wood resources. The older generation usually prefers solid wood floorings. They believed that solid wood floorings could be sanded and refinished by a carpenter after being scratched, so it may be passed down to future generations. In reality, UV varnishing technology is used on all modern solid wood floors to provide a durable surface. However, UV paint cannot be applied at home since it can only be dried after being irradiated by UV light at the factory. Furthermore, the humid weather in Taiwan makes solid wood flooring unsuitable. Wooden floorings deform quickly after bulging, which become unusable and should be removed and replaced.

Sectional drawing of solid wood flooring(Image source/KEDING)

Engineered flooring

Engineered flooring is a type of wood flooring designed specifically for island environments. It not only retains the warm feel of solid wood flooring, but also solves the problem of deformation caused by thermal expansion and contraction without the need for expansion joints. It has a solid wood finish on the outside, which is split cut from solid wood. Gluing technology is also used to adhere the solid wood finish to the plywood. Engineered flooring is resistant to moisture and is ideal for humid regions since it does not bulge and expand. The texture and character of solid wood are also perfectly preserved on the surface. The installation quality has also been similar to solid wood floorings. Therefore, engineered floorings has progressively joined the mainstream market and has become the preferred building material for home decorating. Engineered flooring is ideal to be installed in a humid environment like Taiwan. It not only has the texture of solid wood, but also serves the purpose of maximizing resource utilization and overcoming the issues caused by humidity and heat.

►Engineered flooring selection full strategy

Sectional drawing of engineered flooring(Image source/KEDING)

►Engineered flooring selection full strategy

Sectional drawing of engineered flooring(Image source/KEDING)

Engineered flooring has a significantly different surface than regular wood flooring.

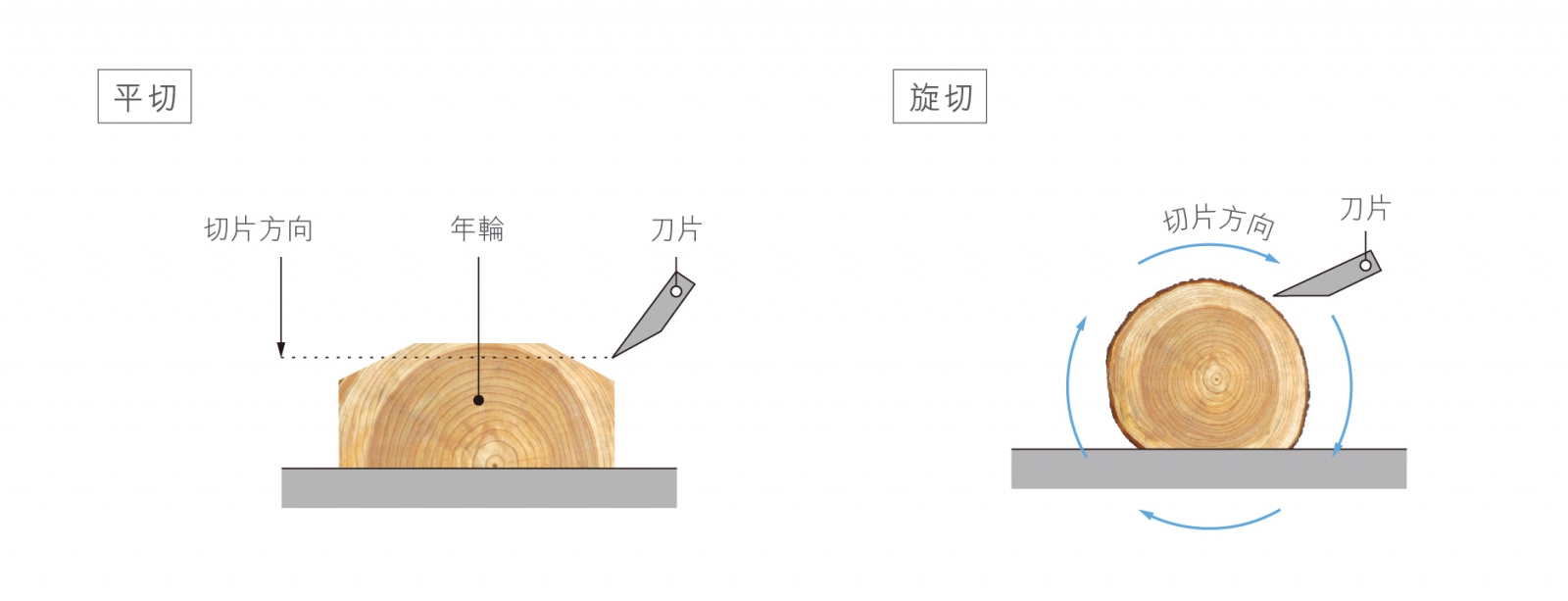

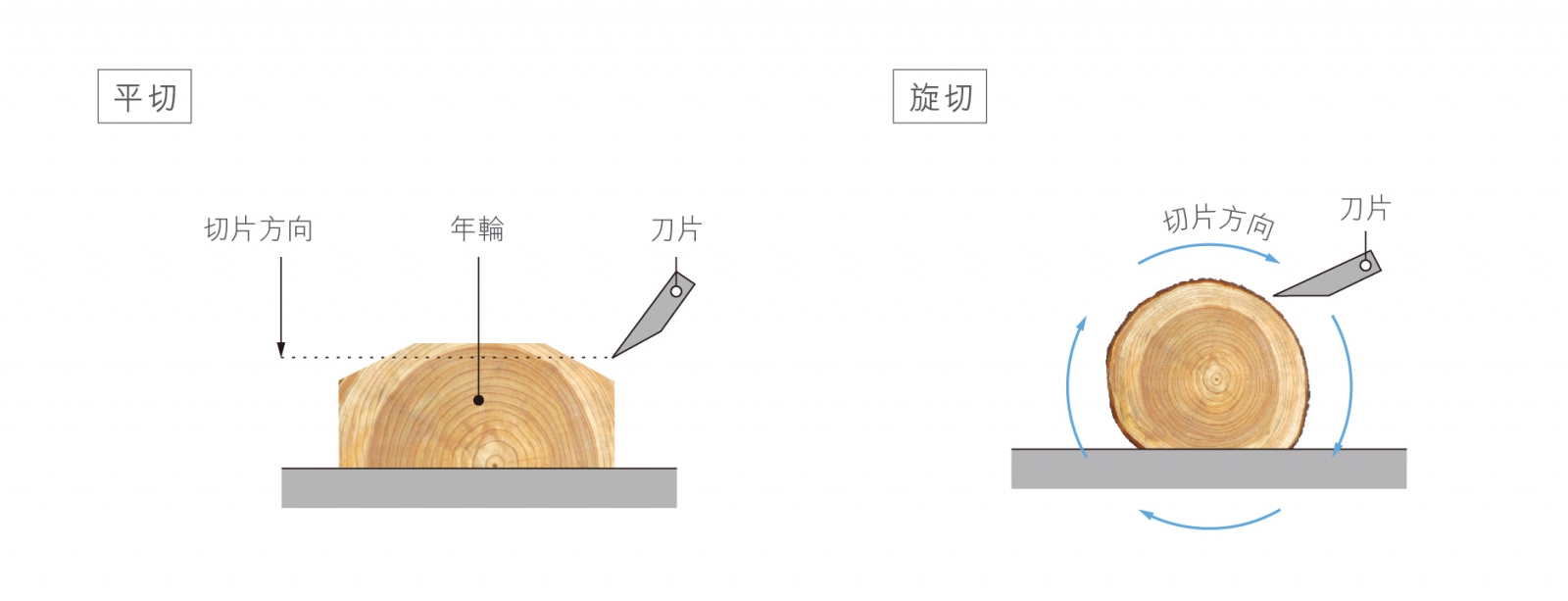

Two methods of creating solid wood on the surface can be used to explain the pros and cons of engineered flooring. Slicing and sawing are the two procedures, and their thickness and structure varies according to the different processing methods.

Image source/KEDING

Image source/KEDING

Image source/KEDING

1. Material collecting method: Slicing

Slicing the wood after soaking and heating it in water for softening. Despite the advantages of a high utilization rate of raw materials with low production costs, the heating process will loosen the wood structure from a molecular scale, which causes the surface paint tends to crack easily in the future. The common thickness is 0.2 to 2 millimeters, which is referred to as "flakes."

Image source/KEDING

2. Material collecting method: Sawing

Sawing the wood directly with a saw blade. Without boiling the wood with hot water, this approach prevents the wood tissue from becoming loose. Sawing has a greater loss rate of raw materials while costing more than slicing, but the molecular structure stays solid which comes with a longer lifespan. The common thickness is 2 to 5 millimeters, which is referred to as "thick sheets”

Laminate flooring

Laminate flooring, strictly speaking, cannot be considered as hardwood flooring since the surface is constructed with a plastic material that has been computer printed to resemble real wood grains and textures, which is not a natural texture of native wood. A dense board (MDF) made of recycled wood powder serves as the substrate. Laminate flooring is inexpensive and scratch resistant, but it has a less realistic texture compared to engineered flooring. The main issue is that the solid substrate board tends to absorb water easily, causing damage to the structure and causing the floor to plunge. As a result, laminate flooring has a relatively short product lifespan. The following comparison table can help you comprehend the three types of wood floorings.

Sectional drawing of laminate flooring(Image source/KEDING)

Sectional drawing of laminate flooring(Image source/KEDING)

Conclusion

KD engineered floorings utilizes a sandwiched structure with plywood to increase structural integrity .While maintaining the textures of real wood, KD engineered floorings also resolve the issues of possible bulging and deforming of traditional solid wood floorings. Made from wood collected by the sawing method, the integrity of wood gets preserved while showing a natural and distinct texture. However, there are numerous engineered flooring options on the market. To choose the most suitable one for you, feel free to refer to the article below, maybe you can become a smart consumer in wood flooring purchases.

BACK TO TOP